Our factory, the Alumíniumárugyár has 100 years of history; it was established in 1899.

It was transformed into a Public Limited Company in 1993. Our company has been producing low pressure, welded aluminium gas cylinders suitable for storing and transporting propane and butane (LPG) gases and refrigerants for industrial and domestic usage since 1949. Gas cylinders of various sizes are manufactured from aluminium discs, with deep drawing.

Our ALUCYL gas cylinders are made in five inner diameters: 180, 205, 250, 290 and 330 mm.

The gas cylinders have the following water capacities: 4.8; 4.86; 6.5; 14.3; 20; 26.2; 34; 50 litres.

Test pressure is between 30 and 33 bar for propane and butane (LPG) gas, and 48 to 50 bar for filling industrial refrigerants.

Our gas cylinders are manufactured according to the standards EN 12862 and 13110, and they meet the specifications of the standards set out in the 2010/35/EU TPED and ADR/RID Directives. The quality of the gas cylinders manufactured by us is certified by TÜV SÜD Industrie Service GmbH Deutschland by marking them with the sign “π “.

Our company meets the requirements of the TÜV Quality Management System according to the standard ISO 9001:2015

We also satisfy special requests. After a type approval process we produce gas cylinders with various diameters or water capacity, even with multiple valves.

Advantages of our aluminium gas cylinders over steel cylinders

ALUCYL gas cylinders made of special Al-Mg-Si alloy have many advantages over steel and any other aluminium cylinders:

- Alucyl are resistant to cold until -50˚C. Steel cylinders cannot sustain temperatures below -20˚C. Usage of the filled gas from our gas cylinder in extreme cold weather without loss is guaranteed.

- Alucyl are resistant to hot air until + 160 ˚C. Safe usage is guaranteed.

- Alucyl resist corrosion and are aesthetic without painting. No inner corrosion hampers the storage of the gas. No repainting or other corrosion protection is necessary, therefore while running expenses remain low, the difference in purchase price returns in a short period of time.

- No danger of sparks during mechanical impacts.

- Due to the clearness and resistance of the special raw-material Al-Mg-Si alloy, they can be used for refrigerant types of gas. No chemical reaction occurs. That is why you or your customer will not have any damage caused by congestion during repairing or maintenance of the air-conditioners/industrial refrigerants.

- Environmental friendly during utilisation, recyclable after disposal.

- Light weight – the empty mass of aluminium cylinders are significantly lighter than steel cylinders of the same volume. Thus their transportation and removal is easier as well as they are more aesthetic.

- High level of safety – the welding joint is at the safest part, on the neck of the Alucyl cylinders.

- Durability – Lots of our gas cylinders more than 60 years old are still in use on the market. Their high quality is retained and their life span is significantly longer compared with the life span of steel cylinders which is approximately 15-20 years.

- Guarantee – 50 years in case of proper use. (The product shall not be impacted by mechanical damages and any chemicals, except for gases permitted for filling. The 50 years guarantee does not involve the valve and design painting).

Unique advantages; a comparison of aluminium and steel cylinders, taking special local climatic characteristics into consideration:

Aluminium cylinders are much more resistant to salty sea air than steel cylinders, thus the life span of cylinders used on ships, at or near seaside is considerably longer. No repainting or other corrosion protection is needed; therefore, your maintenance costs are much lower than that of steel cylinders. Due to the low weight their transportation and handling is significantly easier.

Aluminium cylinders are much more resistant to salty sea air than steel cylinders, thus the life span of cylinders used on ships, at or near seaside is considerably longer. No repainting or other corrosion protection is needed; therefore, your maintenance costs are much lower than that of steel cylinders. Due to the low weight their transportation and handling is significantly easier.

Alucyl has a technically exceptional and unique construction. Thanks to our innovative technology, welding joint is found at the neck of the cylinder, where the stress under pressure is only 1/9 compared with traditional cylinders welded at the centre by a different producer. Thus our products are much safer and have a longer lifetime.

References

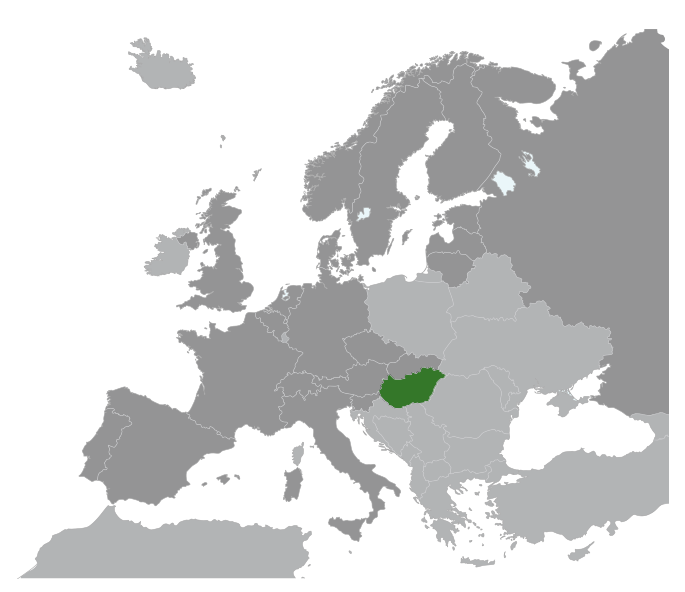

In the past decades Alumíniumárugyár ZRt. has produced over 9 million aluminium cylinders, of which cca. 3 million pieces have been sold abroad.

Our clients all over the world have our products assessed and approved by their own national authority; our products always meet the requirements.

Our gas cylinders are used in almost all European countries, as well as on other continents.

We would be pleased to serve our potential customers with individual or standard needs with our high level of expertise and competitive prices.

If you require further information on a price quote, please contact us at sales@alurt.hu

Utilizations areas

- For energy-supply purposes

Household cooking and heating equipment, caravanning, camping, sailing, yachting. Test pressure is between 30 – 33 bar for propane and butane (LPG).

(4.8L, 6.5L, 14.3L, 26.2L, 34L, 50L)

- As fuel-tanks for industrial forklifts

Test pressure is between 30 bar for propane and butane (LPG).

(26.2L, 34L)

- For filling industrial refrigerants

Test pressure is between 48 – 50 bar for refrigerants.

(4.86L, 14.3L, 20L)

Refrigerant gases which can be filled into the cylinders

R22, RS24, R124, R125, R134a, R142b, R143a, R227, R240FF, R404A, R407A, R407B, R407C, R410A, R410B, R413A, R417A, R419A, R422A, R422D, R437A, R507, R507A, ammonia. Types of the gases are only informing data.

| Volume | Type | Test pressure |

Tara mass |

Filling mass |

Outer Diameter |

Height | Gas |

| 4.8 L | 518.233 | 33 bar | 1,8 kg | 2 kg | 186 mm | 258 mm | propane and butane |

| 4.86 L | 518.230 | 50 bar | 2 kg | varying | 186 mm | 340 mm | refrigerants |

| 6.5 L | 521.101 | 33 bar | 2,15 kg | 2,7 kg | 212 mm | 258 mm | propane and butane |

| 14.3 L | 525.246 | 33 bar | 5,4 kg | 6 kg | 256 mm | 495 mm | propane and butane |

| 14.3 L | 525.241 | 50 bar | 5,8 kg | varying | 258 mm | 495 mm | refrigerants |

| 20 L | 529.242 | 48 bar | 6,9 kg | varying | 298 mm | 516 mm | refrigerants |

| 26.2 L | 529.244 | 33 bar | 7,2 kg | 11 kg | 298 mm | 610 mm | propane and butane |

| 34 L | 529.254 | 30 bar | 8,2 kg | 14,3 kg | 298 mm | 725 mm | propane and butane |

| 50 L | 533.140 | 30 bar | 11 kg | 21 kg | 338 mm | 820 mm | propane and butane |

Wall thickness is between 3-4 mm depends on type. Propane butane nominal filling ratio is 0.42 L/kg.

Beside ethylene oxide (C2H4O), helium (He) and sulphur dioxide (SO2) can be filled into the cylinders as well.

Types of gas cylinders

Volume 4.8 L Filling mass 2 kg

Type 518.233

Gas propane and butane

Volume 6.5 L Filling mass 2,7 kg

Type 521.101

Gas propane and butane

Volume 14.3 L Filling mass 6 kg

Type 525.246

Gas propane and butane

Volume 26,2 L Filling mass 11 kg

Type 529.244

Gas propane and butane

Volume 34 L Filling mass 14,3 kg

Type 529.254

Gas propane and butane

Volume 50 L Filling mass 21 kg

Type 533.140

Gas propane and butane

Volume 4.86 L

Type 518.230

Gas refrigerants

Volume 14.3 L

Type 525.241

Gas refrigerants

Methods of transportation

Palletized

Placed by the line, protected by corrugated paper

Countries where our product are distributed

Austria

Belgium

Czech

Republic

Denmark

Estonia

Finland

France

Germany

Hungary

Italy

Latvia

Lithuania

Netherlands

New Zealand

Norway

Portugal

Russia

Slovakia

Slovenia

Spain

Sweden

Switzerland

United Kingdom

Certificate

certificate download

certificate download brochure download

brochure download